The Savin’side methodology, created by Manutan is designed to assist large companies in the optimisation of their tail spend through six key levers. This case takes a look at an industrial company that is tackling two levers simultaneously: the rollout of the contract and the digitisation of transactions.

Overall mapping

Employees: 6,000

Expenditure at Manutan/year: €392,000

Orders placed/year: 1,799

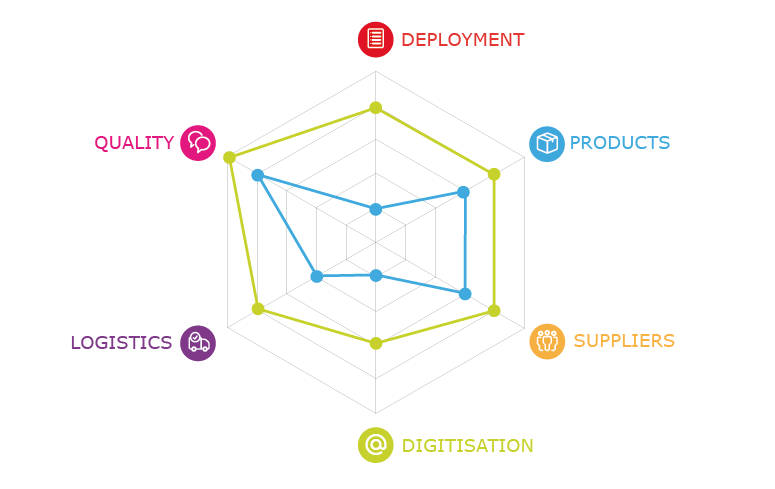

In the example below the blue line represents the initial situation and the green line represents the company's progress objectives for the six levers. The total potential savings are calculated for each lever, and an improvement plan is submitted to the customer.

The company has room for improvement in:

- The rollout of contractual benefits negotiated for the procurement of its products, as preferential pricing conditions are not being applied to all orders;

- Process digitisation, which is not optimised for all operations, resulting in additional costs due to the multiplication of transactions;

- The process of making products available to users, which is beset by problems such as, long transport and waiting times for users to receive the products they need, and manual stock management, which leads to shortages.

From the three lines of improvement identified, the company prioritises its needs and begins by optimising contract rollout and the digitisation of its transactions.

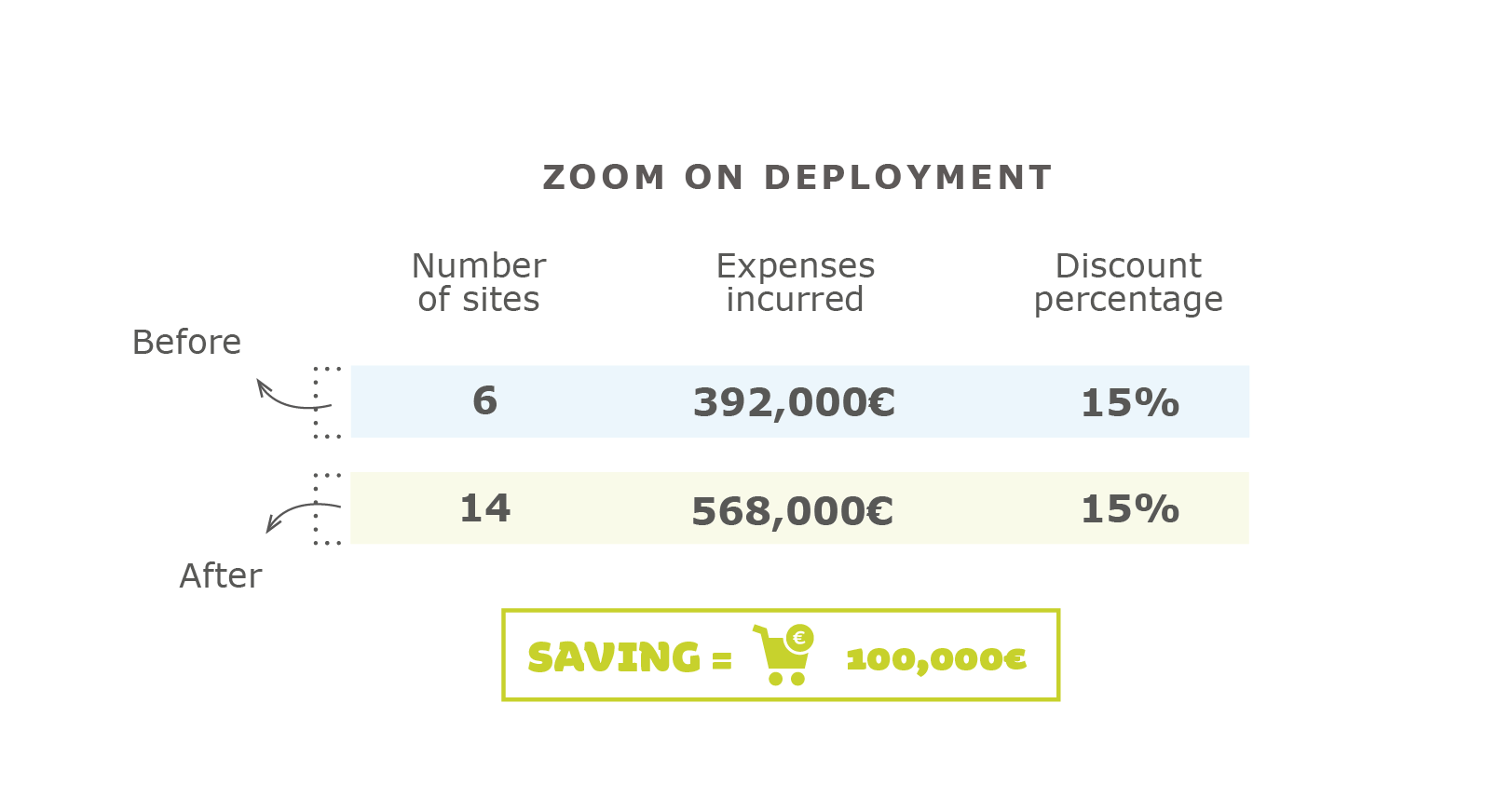

Contract rollout

Previously, only 6 out of 14 sites have been placing orders under the contract negotiated with Manutan, which includes a 15% discount. The Manutan Key Account sales representative, together with the customer, draws up a plan for visits to all of the sites to:

- present the contract and its advantages to the users

- share the feedback and experiences of the six starting sites

To this end the sales representative can rely on a solid network of regional sales reps to act together, quickly and efficiently.

Thanks to this rollout plan, the total procurement amount for the 14 sites comes to €568,000 – enabling them to save nearly €100,000 thanks to the preferential tariff conditions.

In addition to this discount, the customer also gets procurement under control. This translates into total visibility on expenditure in real time and regular in-depth reports from the Manutan teams.

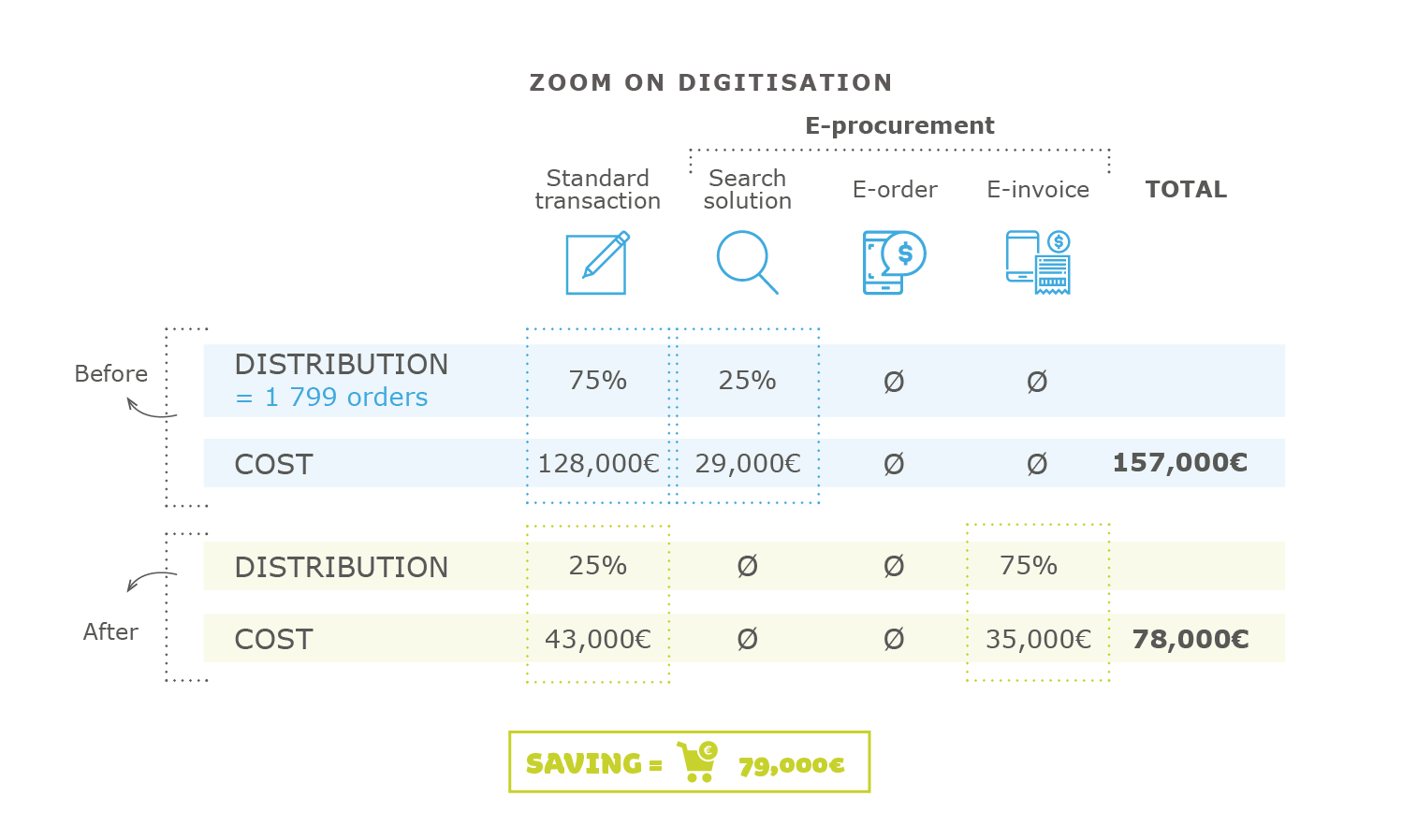

Digitisation of transactions

Initially, only 25% of the orders are digitised via the use of a Punch-Out. Manutan assists the customer during the contract rollout, proposing a full communication kit to promote this tool (thematic email campaigns, tutorial, game contest…). This action plan pushes the order dematerialisation rate up to 75%, fulfilling the objectives of the customer.

With the average cost of standard orders estimated at €95 and that of digital transactions averaging less than €30,* the savings realised by the company amount to €79,000.

Moreover, now with automatised orders, it significantly reduces processing time and the rate of complaints.

Thanks to a tailor-made progress plan, the customer saves a total of €179,000 by activating these two levers. With these objectives achieved, the customer moves on to the optimisation of the logistics processes. After six months additional analysis is carried out to confirm the objectives have been met and to identify the next optimisation routes to be taken.

*Source: APECA