Manutan started working in the field of e-commerce over 15 years ago. These first steps into the digital world proved to be just the start of the company's digital transformation. Manutan is now working on the end-to-end digital transformation of its supply chain. With the pace of technological innovations and the ever-evolving needs of customers, the company felt that it had to engage in a process of even quicker and deeper change.

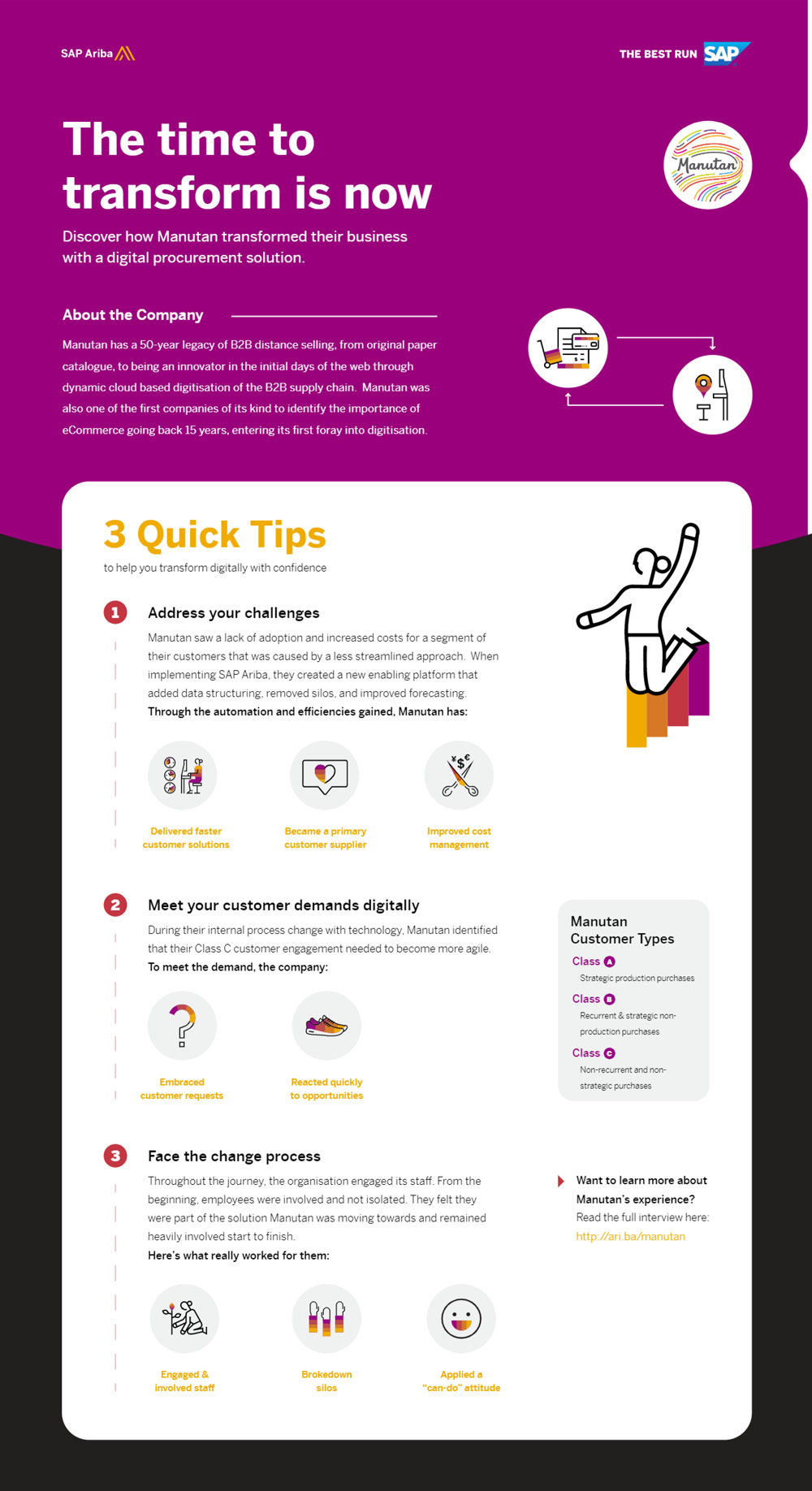

As Manutan's technological partner, SAP asked the recognised e-procurement pioneer to share its experience of the digital transformation process. In this article [1], Xavier Laurent, Manutan's Director of Value-Added Services, emphasises that their digital transformation succeeded based on a combination of four key principles:

- Focusing from the outset on the segment that displayed the highest level of inefficiency — tail spend

- Taking time to identify exactly what was wrong with the initial process

- Adopting a holistic approach by tackling all the stages of the customer journey at once

- Ensuring maximum ownership by involving teams in the project from the start

First principle of supply chain digital transformation: target the right areas

Manutan was aware of a problem: rising costs and low volume growth in the segment of tail spend, or in other words, non-recurring and non-strategic purchases.

By their very nature, tail spend are likely to escape the attention of management teams. In reality, however, the scope for efficiency gains is particularly large in this segment.

To maximise its gains from a digital transformation process focused on tail spend, Manutan decided on a multifactorial approach:

- Improving processes, for example by ensuring that the company was in a position to handle every customer request without difficulty

- Cutting management costs

- Reducing the number of suppliers

- Making the company more proactive so that no opportunity was missed

Second principle of supply chain digital transformation: pinpoint the current problems

Manutan set up a project team made up of customer project managers and purchasing consultants. This ad-hoc team worked in partnership with a panel of the company's customers to identify the latter's needs. Discussions centred around customer expectations, and findings were passed on to other areas of the company: IT, supply chain and finance.

This analytical work revealed three main areas for potential progress:

- Making data structured, since the portion of unstructured data relating to tail spend is generally estimated to be around 80%

- Eliminating silos, as an essential preliminary step for any rational and comprehensive approach to the challenge of digitalising tail spend

- Forecasting needs more accurately, not only in terms of volumes, but also in terms of schedules and locations (how many?, when?, where?)

The time spent analysing manual processes for tail spend and the problems they cause proved to be time well spent, since Manutan was able to cut overall costs for its customers by two-thirds.

Third principle of supply chain digital transformation: act on the customer journey as a whole

Manutan therefore decided to make the tail spend process much more agile for its customers. The overarching goal was the end-to-end digital transformation of all the stages of the customer journey.

Manutan saw it as its duty to provide its customers with a faster, smoother, more ergonomic and (of course) an entirely needs-based experience. It also wanted a solution that could be adapted to the specific demands of each of its customers. Functions such as the analytical processing of transactions and report generation did not escape the attention of the project team either.

The digital transformation of processes focused in particular on:

- Product showcasing

- Consultation, validation and ordering stages

- Repeat orders

- Delivery

- Invoicing

- Analysis and reporting

Fourth principle of supply chain digital transformation: embrace change

Right from the outset of the digital transformation project, Manutan encouraged its employees to take ownership of the process by giving them the freedom to say yes or no to customers. Increasing employee involvement led to a more positive attitude towards the company's new systems and stronger partnerships with customers.

One key feature of Manutan's corporate culture is that its employees are allowed to speak to customers directly. Information is no longer filtered through intermediaries or passed down long chains, meaning that outcomes can be achieved more quickly and the company's customers have a better overall experience.

The conclusion is clear — the digital transformation of Manutan's supply chain has been a success story that has benefited not only the company, but also its customers and employees.

Customers are better off in all respects — accuracy, speed, flexibility, effectiveness and cost reduction. And Manutan employees have adopted a "can-do" attitude, true to the company's motto.

If you would like to know more before embarking on the digital transformation of your supply chain, further information can be found in the article "Two approaches to digitalising purchasing departments".

[1] Supply Chain Transformation with SAP Ariba and Manutan