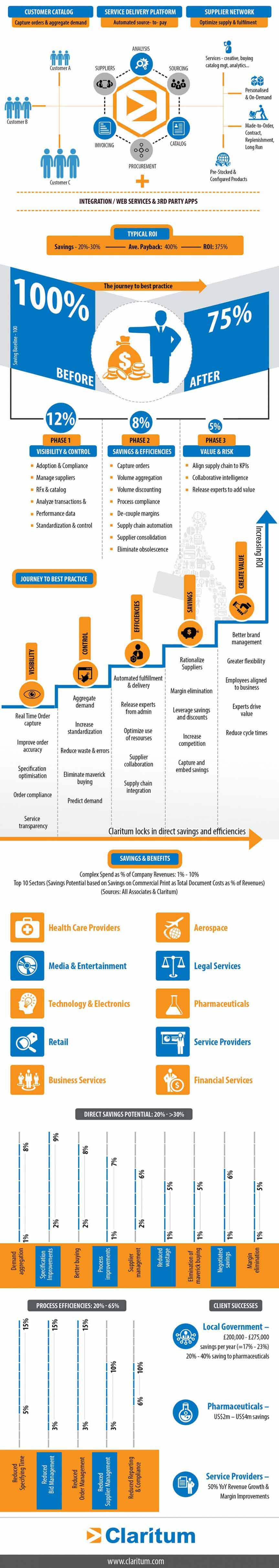

The Claritum e-procurement solutions editor has put together an easy-to-read infographic containing everything you need to know to undertake a complete purchasing digitalisation project. Purchasing departments will most likely find this resource very helpful when convincing executive officers to commit resources and manpower to an e-procurement project. This detailed and accurate diagram, backed up with statistics, certainly warrants a closer look, and sums up the digitalisation of purchasing in 80 seconds.

E-procurement: Why?

A digital Procure-to-Pay platform combines three major functions: access to a digital catalogue, dematerialised ordering and dematerialised invoicing. To establish Source-to-Pay, a broad-based solution for listing new products, three additional functions are included: the identification of new suppliers, the evaluation of suppliers and their integration into the catalogue of target products.

According to Claritum, adopting an e-procurement platform will allow you to save an average of 25% across all purchases if you follow the three steps outlined in the infographic:

- Phase 1: visibility and control (supplier management, standardisation, etc.)

- Phase 2: savings and efficiencies (volume aggregation, supply chain automation, etc.)

- Phase 3: value and risk (collaborative intelligence, release experts to add value, etc.)

E-procurement: How much?

If we look in detail at the savings made by implementing an e-procurement platform, the Claritum infographic differentiates between potential savings for the average basket and potential savings resulting from productivity gains in purchasing processing.

1. Reduction of costs

Claritum identifies nine factors which all contribute to an overall cost reduction of more than 30% in comparison to before the solution was introduced. Claritum attributes the highest contribution to direct cost reduction to better matching purchasing requests with real needs, aggregating orders and creating improved purchasing conditions, in that order.

2. Productivity gains

Based on fewer criteria, productivity gains represent a savings potential of between 3 and 15% depending on the criteria. Over the course of a year, standardising products to save time specifying purchasing requests, signing agreements with general suppliers to save time managing tenders and automating processes to save time spent handling orders, can altogether represent a reduction of 10 to 45% in processing costs. Furthermore, if you then consider the productivity gains generated by the reduction in the number of suppliers and automated reporting, an organisation can expect to reduce their purchasing processing costs by between 20 and 65% as a result of e-procurement.

The majority of purchasing departments are involved in the digitisation of purchasing processes. The idea here is to think of digitalisation as a fully-integrated approach, with a global platform, to potentially benefit from a 375% return on investment.