In the era of the digital revolution, all companies, private and public, and all professions are impacted by the rise of technological innovations. It means that they all need to rethink their processes, adapt their culture and integrate information on a large scale, especially as these three imperatives dictate a company’s competitiveness and longevity. The procurement function is no exception. As tools develop at a phenomenal rate, the challenge is to make sense of this race towards technological progress. Six new technological innovations are currently standing out in the world of procurement.

Technological innovations to meet new challenges

Investment in technology has evolved significantly in businesses over the years, extending beyond research and development departments. For procurement departments, annual investment forecasts have increased by 30% over the last two years. Nevertheless, they are reviewing their digital roadmap to adapt it to the current economic situation, characterised by inflation and supply tensions.

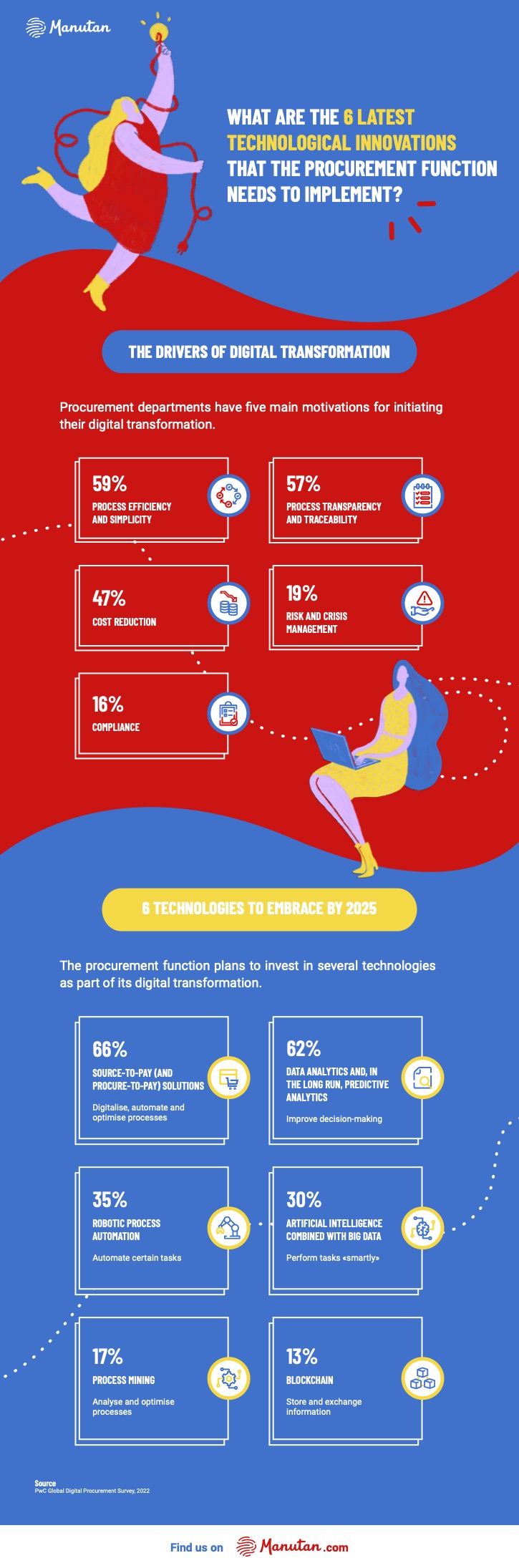

For procurement decision makers, digital transformation must now contribute to:

- Process efficiency and simplicity;

- Process transparency and traceability;

- Cost reduction;

- Risk and crisis management;

- Compliance.

Companies are therefore looking for performance and security. They are moving away from experimentation to focus on solutions that add value with proven use cases.

Simultaneously, they also intend to streamline the number of technology tools to be rolled out. The latest study by PwC about the digitalisation of the procurement function shows that companies are moving from an average of 3.6 technology tools used in 2019 to 2.2 in 2022. The trend is therefore leaning towards companies carefully selecting tools to help them get through this critical period.

Six major technological innovations that make a difference

Although it was once on the sidelines of this technological evolution, change is far from new to the procurement function, which has long since kickstarted its digital transformation. In the current tense economic circumstances, companies are increasingly interested in new technologies to achieve one goal: Becoming more competitive in order to establish their place in the market.

1. Source-to-Pay (and Procure-to-Pay) solutions

Source-to-Pay (S2C) solutions have become a must for procurement departments, as have Procure-to-Pay (P2P) solutions. And for good reason! According to the PwC study again, 9 out of 10 companies are equipped with at least one, if not both, of these types of technology. These tools are mainly designed to digitalise, automate and optimise procurement processes, from sourcing to payment (Source-to-Pay) or from product research to payment (Procure-to-Pay). In addition to this tremendous efficiency gain, these technologies also serve to consolidate data and improve visibility and control over spending.

2. Data analysis

The digitalisation of procurement processes has naturally led procurement departments to use another technology: Data analytics. This enables buyers to learn lessons and guides their decision-making, both operationally and strategically.

PwC also points out that 82% of companies that are especially advanced in digitalising their procurement processes believe that they create value out of their procurement data. Eventually, they should also become familiar with predictive analysis in order to identify new and future trends.

3. Robotics (and more specifically RPA)

Robotic Process Automation (RPA) plays a key role in the digital transformation of the procurement function. Through this innovation, companies can execute pre-programmed actions, following well-defined arbitration rules.

It can be extraction, transfer or even data entry, for example. The aim is to free the procurement and finance teams from manual and time-consuming tasks so that they can put their energy into higher value-added work.

It is also important to note that this type of technology can be rolled out in just a few weeks, with lower implementation costs.

4. Artificial Intelligence (AI)

Artificial Intelligence, combined with Big Data, is in full development and the use for these technological innovations is becoming ever clearer in the procurement world. This technology encapsulates a whole set of techniques, processes and applications for performing tasks in a "smart" way.

The European Parliament refers to this innovation as "systems that display intelligent behaviour by analysing their environment and taking actions – with some degree of autonomy – to achieve specific goals". In this sense, there are many applications, such as contract management, supplier risk management, performance management, etc.

5. Process mining

Process mining is relatively unknown in the procurement function, yet it is very helpful for this particular area of business. This technological innovation enables buyers to analyse operational processes using data from a company’s various systems in order to better understand them and, ultimately, to identify potential areas for optimisation (delays, inefficiencies, etc.). It helps procurement departments to improve overall productivity and reduce maverick spend, exploring the root causes of possible malfunctions.

6. Blockchain

Although blockchain is a source of value, procurement decision makers do not yet have a clear vision of its use cases. Few companies are therefore capitalising on this innovation but their number has remained stable over the years.

Yet it has tremendous potential, as Robert Greifeld pointed out when he was still chairman of Nasdaq: "[Blockchain] is the biggest opportunity set we can think of for the next decade or so". This technology enables companies to store and send information simply, transparently and securely. This would allow procurement and supply departments to improve traceability and speed up processes.

Procurement departments have a clearly stated ambition for using technological innovations: To boost their performance so they can contribute to their company’s growth. Whatever the technological innovations (Source-to-Pay, data analytics, robotic process automation, etc.), the bottom line is always about saving time, energy and resources.

For procurement departments to successfully digitalise their processes, it is important for them to work in stages, starting with an inventory of the current situation without overlooking the main obstacles to implementing each technology (data quality, lack of integration, etc.). Using planning like this as a basis, they will be able to define their roadmap, as well as their priorities in terms of emerging technologies.