Ad hoc purchases designed to meet a non-recurrent, non-strategic demand costs companies a lot of money. These "unscheduled" orders incur processing costs that could be avoided and purchasing costs that could be controlled. There are many solutions to avoid ending up in pressing situations or, more accurately, to avoid paying the consequences for them. But in order to get unscheduled purchasing under control companies need to change their practices and apply a different setup at all levels, or even implement a system where there isn't one already in place. A survey carried out by Manutan Belgium among its customers highlighted a number of practical ways to work differently…

Time-consuming, out-of-control purchases

The figure is well-known: unscheduled purchases represent 5% of company purchases and 70% of processing costs on average. This survey carried out by Manutan Belgium (1) highlights the relationship between this financial data and the behavioural data reported by the stakeholders themselves. Firstly, ad hoc purchases take up buyers' time. 57% of buyers said that most of their orders were ad hoc, responding immediately to requests from users. Secondly, unscheduled purchases are not planned. At best—and this covers the majority of situations—buyers group orders based on need. 8% rely on their suppliers to anticipate stock outages, and only 11% of respondents said they had an annual schedule and stuck to it. Most companies only bought salt for spreading on the roads, fans or protective clothing at the time they actually needed them!! Finally—and this is a consequence of the above two points—unscheduled purchases are not controlled financially. For 18% of companies, there is no budget assigned to this. The urgent situation in which the buyer is placed renders the question of price a secondary issue...

Purchases that cost the company dearly

The price of unscheduled purchases is subject to little or no negotiation and the total cost of ownership (TCO) is particularly high due to processing costs. Given that supplier management never represents less than 1000 euro per year, it's easy to imagine the hidden costs of an ad hoc purchase from a company with whom no other orders will be place in that the year. The third component of TCO is the shortfall linked to low bulk procurement. Buying as a matter of urgency, off-season, based on user specifications and sometimes with no annual budget, is not the best way to benefit from volume purchasing.

Unscheduled purchases often bypass internal systems as they are essential to corporate operations, but are not recurring and not strategic in terms of core business. So controlling ad hoc purchases represents another potential and significant source of savings at the organisational level. For reasons also associated with a multitude of stakeholders and dispersion across sites, issues such as quality monitoring, order history, consistency of ranges and, of course, efficient logistics, are not adequately addressed in such a context.

So are ad hoc purchases a lost cause?

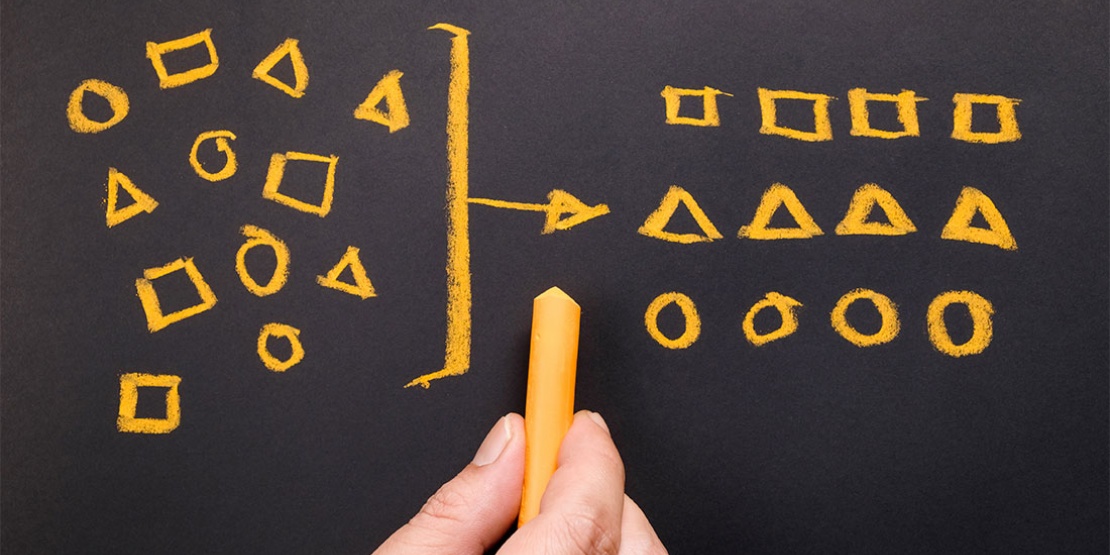

No, there are plenty of solutions to choose from! Centralising orders with one distributor that can replace a number of non-strategic suppliers is a proven route. The key to this system is the option to streamline ranges, make bulk purchases and regulate logistics. Especially if this distributor is able to offer companies a digital Procure-to-Pay solution that automates order processing and renders it paperless. Another route, which can also be combined with the first, is to have industrial automatic dispensers installed on the premises. Users retain control, urgent situations are handled, but purchases fall within the overall control process.

(1) Survey carried out by Manutan Belgium with 359 buyers of office supplies in industry, construction, logistics, and transport and services sectors.