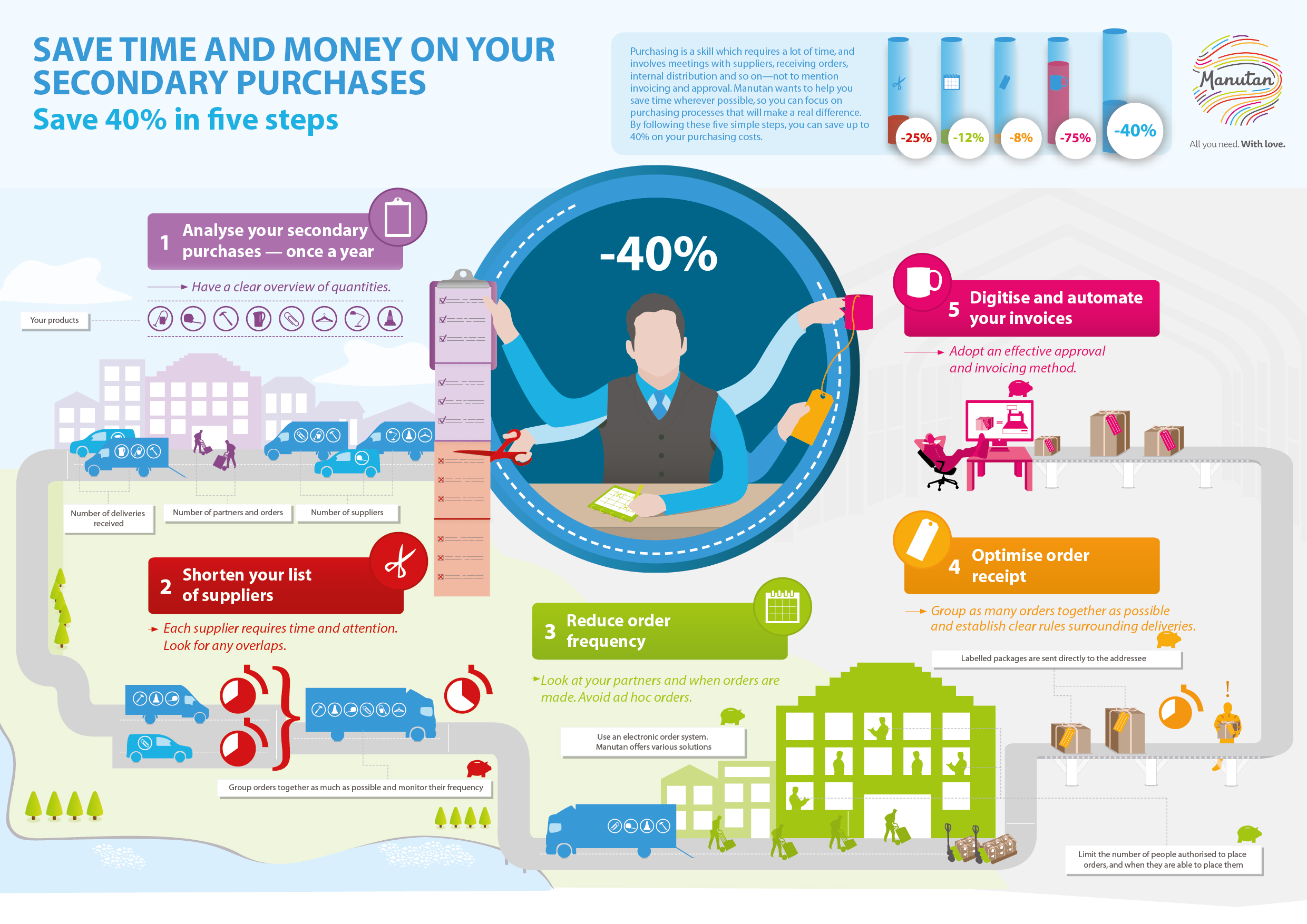

On average tail spend account for 70% of the processing costs for 5% of the total value of purchases within an organisation. Multiple suppliers, urgent orders, ad hoc deliveries etc. The reasons add up to the detriment of the total cost of ownership (TCO). However, this is avoidable and getting unscheduled purchases under control is possible. It needs organisation, perseverance, resources, persuasion, and above all a good partner. There are five easy steps, with a savings potential of 40%.

1. Analyse your annual purchases

The first stage involves getting a more accurate picture of your tail spend. But when referring to unscheduled purchases, tail spend, ad hoc purchases, what exactly do we mean? Which families? Which products? Who orders what? How many? For whom? And how many receipts and returns does that generate?

These questions should be asked globally and per site to enable you to target your action plans.

2. Pare down your list of suppliers

Managing a supplier is an expensive business, costing 1000 euro per year on average. And some suppliers only account for a few orders per annum. There are probably ways to group certain purchases with a single supplier, with three key benefits: reduced processing costs, better pricing terms and a lower number of deliveries.

3. Reduce order frequency

Urgent orders, needed immediately, are costly. The supplier is in a strong position as regards prices and terms; logistics are stretched and procedures are often overlooked. Although real urgent situations do crop up, most ad hoc purchases could have been anticipated. By looking at order histories, thinking about seasonal requirements (salt is needed for the roads every winter, but that doesn't mean that an order should only be placed when the first frosts appear), building up buffer stocks, giving your partners responsibility for notifying you or even sending supplies according to a set frequency, you take back control of most of the tail spend families.

4. Optimise order receipts

Receiving orders often requires input from a large number of people, from reception at the gate to the end recipient. Each step demands time, synchronising availability demands energy; waiting or causing people to wait is a waste of time. Organisation, teamwork and, in particular, good common sense will result in gains in productivity. Changes can be made, for example, to the number of people authorised to place orders, to the hours in the day when deliveries can be received, to labelling packages, without you having to track down the recipient. Savings can be made site by site and everyone will benefit.

5. Digitise and automate your invoices

Paperless invoicing and automated processing using Electronic Data Interchange (EDI) have proved their worth in terms of productivity. A number of solutions can be explored to benefit from a Procure-to-Pay system: having your own platform, utilising a B2B marketplace or choosing an advanced distribution partner that can offer technological advantages via their e-commerce site.

Each of these steps is a potential savings option in itself. And coordinating implementation with the right partner is essential for optimising productivity gains and reducing your costs!