In the future, the main challenge for procurement officers will centre on value creation and its role in supporting the reinvention of their companies' business models. To do this, procurement officers can start by optimising the procure-to-pay process, which, when properly managed, can achieve significant savings and improve efficiency, meaning time can be devoted to tasks with higher added value instead.

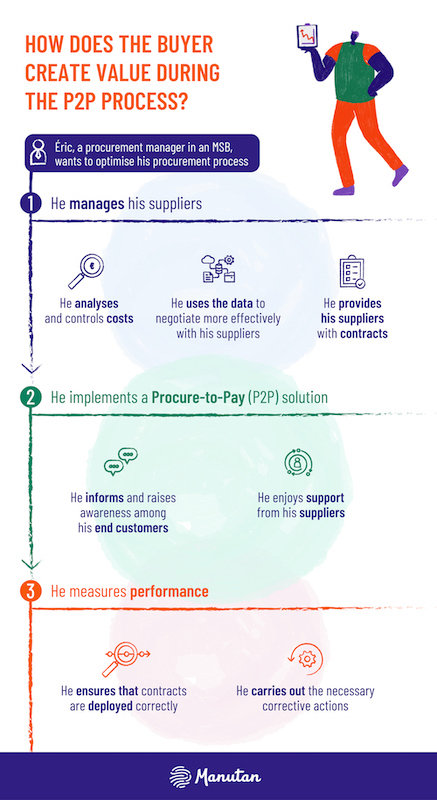

Let's take a look at Eric, a procurement officer at a mid-sized company, who is going to follow three key steps to create value:

1) He manages his suppliers

With the supplier-assessment period fast approaching, Eric reviews the situation. He starts by analysing supplier expenditure over the past year, by comparing the reality against the company's strategy, which focuses primarily on accelerating digitalisation and reducing costs during the ongoing health crisis.

He meets with his key partners and uses a detailed report that draws on his Business Intelligence solution to assess the situation. To make sure that everything is aligned with the company's strategy, Eric negotiates the implementation of a PunchOut solution and volume discounts.

2) He implements a procure-to-pay solution

Once the e-procurement solution is integrated with his company's ERP, Eric and the partner distributors focus on informing internal customers of the new pricing and this new digitalised ordering process. In particular, they raise awareness of the benefits of paperless transactions in reducing hidden costs. Eric calculated that this would mean significant savings of almost 50% per transaction.

To ensure that the results actually materialise, they are also working hand-in-hand to develop a deployment campaign that includes emails and visits to critical sites where contracts are not being deployed effectively.

3) He measures performance

Each quarter, the distributors submit a report containing the KPIs determined previously with the procurement officer. Together, they track the deployment rate, site by site, and take corrective action where necessary.

In addition to strengthening its relationship with these suppliers and optimising its entire procure-to-pay process for the benefit of internal customers and procurement teams, the company decides to take a further positive step in its digital transformation. It reinvests the savings made in a long-awaited development project for the finance department: the automation of invoice processing using an optical-recognition solution. What's more, it gets better control of spending and improved efficiency for teams into the bargain.